Gene therapy relies on the delivery of specifically modified DNA sequences into cells, commonly by means of an adeno-associated virus (AAV Gene Therapy).

AAV-mediated gene therapy holds a transformational potential within the gene therapy treatment landscape. 2023 saw a record-breaking number of FDA approvals for biological medicines. Those approvals include two different groundbreaking AAV gene therapy products, one for treating hemophilia A and another for treating muscular dystrophy in pediatric patients.[1] Several additional AAV gene therapy products are in Phase II/III of clinical testing. Biological buffers are needed at every stage of gene therapy development and manufacturing, creating a unique opportunity to help standardize and boost the entire production process by optimizing buffer formulation.

AAV Gene Therapy Manufacturing Challenges

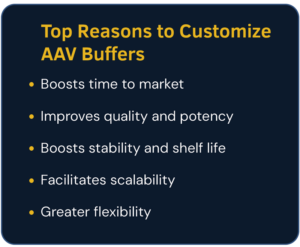

Accelerating clinical development of gene therapies is highly desirable, yet the pharmaceutical industry still faces significant challenges, primarily concerning process variability and scalability. Custom buffer formulation can help mitigate these challenges, speeding AAV therapeutics to market.

AAVs are the most commonly used vector platform for gene therapies because they offer several advantages, including a strong safety profile, stable expression, and the fact they are relatively easily targeted to specific tissues. Nevertheless, variability in parameters such as transduction efficiency, viral titer, and purity can significantly slow the downstream development process. Likewise, challenges in manufacturing platform flexibility, packaging, and buffer formulation make AAV therapy scale-up a labor-intensive process, particularly where regulatory compliance is concerned, since each raw material supplier and process must be validated and documented.

The overall purpose of downstream processing is to produce a highly purified product with as little loss of the active component as possible. Purification, whether by affinity chromatography or density gradient centrifugation, entails multiple steps, each carrying a risk of further capsid loss.[2] Low transduction efficiency or too high a ratio of empty capsids means the purification process will need to be repeated or redesigned to achieve an acceptable yield. Adenoviral vectors lacking the therapeutic DNA sequence lower the overall potency of the product. The incidental inclusion of components from leaky capsids or other process contaminants increases risk to the patient. Early optimization of biological buffers via customization protects the stability and purity of AAV vectors at each step of the purification process. This creates efficiency by saving the time and money needed to troubleshoot inconsistent manufacturing runs.

Process scale-up for commercialization presents several more potential pain points. Dealing with higher buffer volumes can potentially introduce a higher volume of process contaminants. Again, custom buffer manufacturing helps mitigate this risk by ensuring that pH and osmolality are specifically suited to the manufacturing platform, and designed to enhance purification efficiency. Buffer solution packaging will need to transition from low-volume glass or plastic bottles to high-volume bags or drums, necessitating another round of screening to ensure changes do not affect critical quality attributes of the AAV gene therapy product.

Finally, since FDA regulatory guidelines require robust characterization of the final product that will be administered to patients, all biological buffers and other raw materials must be qualified and documented to meet GMP standards. This can sometimes necessitate changes in sourcing to accommodate manufacturing capacity, as well as the switch from RUO to GMP-compliant processes and materials.

Accelerating Downstream Processing

In order to create greater efficiency in AAV manufacturing, downstream processing buffers should be optimized and standardized as early as possible. This creates a robustness that saves time and labor as candidate therapeutics progress from early-stage development through to clinical testing and commercial manufacturing.

Flexibility is another key consideration. A flexible custom buffer manufacturing platform can be used to optimize any buffer, for any AAV serotype, and any purification method. Developers should look for buffer suppliers that are flexible in terms of formulation, packaging, and scalability. Nucleus Biologics has the depth of experience needed to expedite and scale both standard and custom buffer manufacturing. Buffers can be ordered quickly and seamlessly in quantities ranging from 0.5L-1L bottles, to bags or drums of up to 2,000L.

Ideally, buffer suppliers should have onsite GMP capability, to provide a smooth transition from early-stage research to clinical candidate development. Early transition from RUO GMP-compliant materials simplifies scale-up and assures that sourcing and regulatory challenges are already met at what is usually a critical stage of therapeutic product development.

AAV-specific bioprocesses are not yet standardized, due to the relative immaturity of the field. Early optimization of downstream processing buffers feeds into a “quality by design” manufacturing platform and streamlines the entire manufacturing process. Nucleus Biologics is uniquely positioned to provide flexible, customized AAV buffer solutions to speed your AAV gene therapy to approval. Please visit our website to learn more.

References

- Senior M. Fresh from the biotech pipeline: record-breaking FDA approvals. Nat Biotechnol, 2024. 42, 355–361. https://doi.org/10.1038/s41587-024-02166-7

- Lam AK, Mulcrone PL, Frabutt D, et al. Comprehensive Comparison of AAV Purification Methods: Iodixanol Gradient Centrifugation vs. Immuno-Affinity Chromatography. Adv Cell Gene Ther. 2023. 2023:2339702. doi:10.1155/2023/2339702